News

3D Printed Model of Processing Plant Enhances Communication, Planning and Training 0

By Joffrey Bouchard-Gorin

Article reprinted with permission from Ausenco.

We are often asked to consider the “big picture” when trying to solve our toughest project challenges, however understanding the “small picture”, and knowing what to focus on, can help create actionable, achievable goals which can make project planning, training and coordination, safer and more efficient.

At Argonaut Gold’s Magino project near Dubreuilville, Ontario, Canada, our Operational Readiness (OR) team has taken a unique approach to improving our client’s collaboration and information transfer, as the construction of their 10,000 t/d gold processing plant nears completion.

Our OR team works in tandem with the project delivery and execution team to provide operational readiness support within the scope of our fixed-price contract. Operating very much behind the scenes, we work closely with our client to ensure their operations team is ready to safely and effectively assume full ownership when the project is finished. Much of this preparation is focused on maintenance readiness – making sure the strategies surrounding preventative maintenance plans and scheduled component change-outs are developed in time for their assets to go online.

Developing a stand-alone “situation room” has allowed us to create an immersive environment for team members to use when coordinating project plans. At Magino, we’ve improved that experience by creating a 1:1000 scale model of their entire processing plant, which vastly improves our ability to visualize and communicate as a team.

“It’s like a helicopter tour of the actual site, without having to leave the boardroom,” says Victor Barua, Argonaut General Manager.

Working with Montreal-based 3D printing specialists MatterThings, the 4’ x 10’ model has been created to be both detailed and interactive, as well as quickly updatable, as new components are introduced due to changes made with the original equipment design. Compared to paper drawings or even 3D computer illustrations, the model feels real and allows for direct interaction – almost as much as being there in person (see below for photos of the model).

“That’s the appealing part,” says José Hoyo, designer and partner at MatterThings. “It allows people to visualize things quickly and holistically. When you’re looking at a model you can picture yourself walking around inside, and it’s a lot easier to make a decision.”

840 individual elements were re-drafted by MatterThings and they used several different 3D printing technologies to provide the right solution for each piece of the model.

Different components are color-coded for quick identification – green for electrical, shades of blue for different pipes, brown and grey for structural elements, etc. At the height of production, 20 machines worked simultaneously in different colors and materials.

With significant experience, these craftspeople know which aspects of the model design are most useful to the end users. “Clients’ appreciate that you can dismantle different parts of the model, take a section, open it up, and look at what’s inside,” Hoyo says.

Modular components like roofs, tanks, and parts of the plant shell are attached with magnets, for example, so they can easily be removed to see what’s inside when necessary, but reattached for more general discussions.

Introducing the model as an added resource in the Magino situation room was a direct result of a strong client relationship. We worked together daily through the iterative process of project execution.

We presented the idea of the model to the client team as value adding and justifiable by demonstrating how it would contribute to better mine safety training and improve the coordination of commissioning activities. We then worked with both our client and our supplier to determine which functionalities would make it most useful, with the goal of producing an interactive learning environment for improved safety learning and culture.

As a unique tool for engineers and contractors to visualize logistics and communicate their ideas and concerns, it helps the team identify flaws and prevent potential problems. That helps reduce lost time and wasted resources and avoids costly mistakes.

For more information on how we can help you #FindABetterWay with your operational readiness, contact Joffrey Bouchard-Gorin.

Photos below of the 1:1000 scale model of the Magino processing plant and on-site infrastructure

- MatterThings Inc.

- Tags: 3D Modelling 3D Printer 3D Printing Ausenco Design Diorama Maquette MatterThings Modelling Scale Model

Pharmaceutical Company Zoetis Inc. Ran the World’s Largest 3D Printed Educational Campaign Across Canada 0

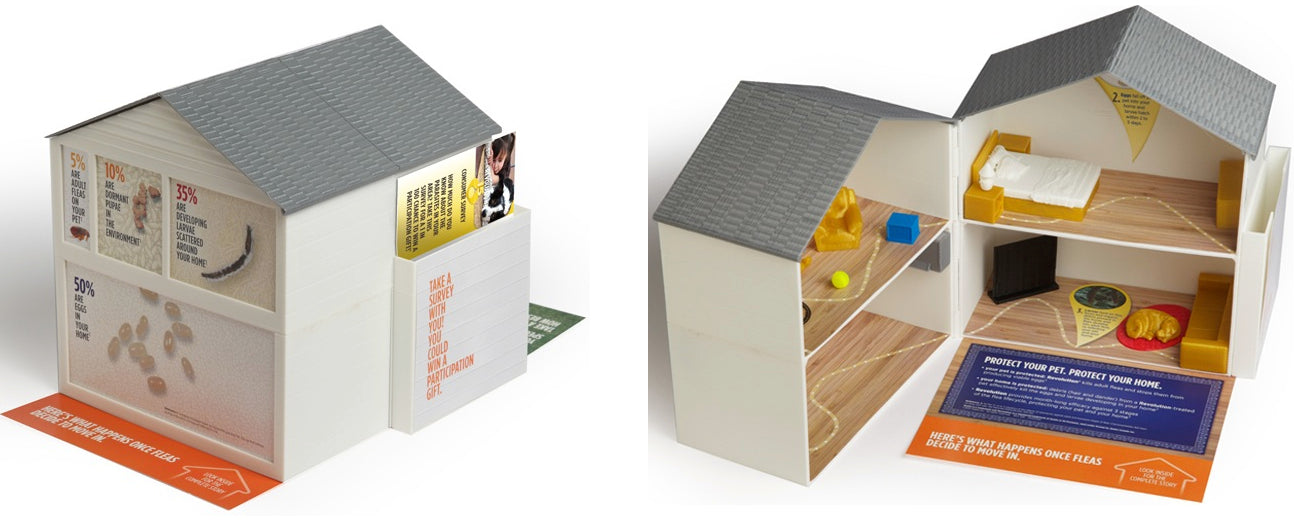

If you stepped into a veterinary clinic in Canada recently, you might have come across this 3D printed "flea" house.

Zoetis Inc., the world's largest producer of medicine and vaccinations for pets and livestock, wanted a unique teaching tool for veterinary staff to educate their clients on the risks of a flea infestation in the home as well as talk to clients about a comprehensive tick control strategy. They therefore ran the world's largest 3D printing and augmented reality based educational campaign across Canada.

CHM Communications, a full-service bilingual advertising agency specializing in strategic and creative thinking together with partner MatterThings - 3D printing services, conceived and executed this project.

The model allows staff to easily illustrate the issues with regards to fleas on pets and in the home, and on the back there is a slot for a handout on tick control and a holder for tick removers for the client to take home.

INTEGRATED MOBILE AUGMENTED REALITY

CHM Communications brought a unique feature to the flea house by having incorporated augmented reality.

Using a downloaded app on your phone or tablet, it would recognize, in this case, the image below which is the back of the flea house. An educational video would then launch about the risks of a flea infestation in the home and how to control it.

MANUFACTURING: 3D PRINTING THE FLEA HOUSES

From design to production, all components of these 440 model houses manufactured for the campaign were 100% made right here in Montreal (Quebec) Canada.

MatterThings - 3D Printing had over twenty of their 3D printers working around the clock for several months to complete the production.

To give you an idea, each room took 4.5 hours to 3D print and 309 g. of PLA bio-plastic on one of their MakerBot Replicator 2 3D printers.

PLA (Polylactic Acid) a food safe bio-plastic derived from renewable resources - corn starch was used to 3D print the houses and furniture. This bio-plastic is very durable and resists many solvents such as acetone, motor oil, gasoline, paint thinner, etc.

MatterThings - 3D Printing Services used every generation of MakerBot desktop 3D printer to build each component of the house. Even their Cupcake and Thing-o-Matic were busy 3D printing mattresses and arm chairs!

To learn more about the following companies visit:

Zoetis Canada: www.zoetis.ca

CHM Communications: www.chmcommunications.com

MatterThings Inc. - 3D Printing

514-312-6060

www.matterthings.com

3d@matterthings.com

- MatterThings Inc.

- Tags: 3D Printing Canada 3D Printing Montreal 3D Printing Pincourt 3D Printing Quebec 3D Printing Services 3D Printing Services Canada 3D Printing Services Ile Perrot 3D Printing Services Montreal 3D Printing Services Pincourt 3D Printing Services Quebec 3D Printing Services West Island 3D Printing West Island Augmented Reality MakerBot Desktop 3D Printer Pharmaceutical Pharmaceutical 3D Printing Zoetis

Folie Technique Custom 3D Printed Headphones Project 0

Students attending summer camp at Polytechnique Montréal took part in an engineering program where they designed custom headphones, and we 3D printed them.

The Program

As part of an initiative to garner interest in the sciences among younger individuals, Polytechnique Montréal organizes a summer camp for ages 7-17 called Folie Technique. At the summer camp, attendees take part in multiple interactive projects which teach them technical skills and help them visualize various scientific concepts.

This program was created in 1991, and has been giving students scientific and technical skills since then. Last year nearly 1400 students attended the summer camp!

The Project

This particular project was part of a series of workshops on mechanical engineering. Starting by teaching students to make and understand technical drawings and 3D models, the students then make technical drawings of their custom headphone designs using a CAD (computer-aided design system).

From there we receive the files and print the students' headphones (only the exterior earpiece, not the headband) in their desired colors. Using PLA, we created more headphones than we can count, and the students seem very happy with their new functional headphones, as you can see!

Have something you want 3D printed? We can help! Our contact information is just below.

MatterThings Inc. - 3D Printing

514-312-6060

www.matterthings.com

3d@matterthings.com

We´re in Pincourt, the West Island of Montreal, Quebec, Canada

- MatterThings Inc.

- Tags: 3D Design 3D Design Pincourt 3D Design Services 3D Design Services Canada 3D Design Services Ile-Perrot 3D Design Services Montreal 3D Design Services Pincourt 3D Printed Custom Headphones 3D Printed Headphone Cover 3D Printed Headphones 3D Printing Canada 3D Printing Engineering 3D Printing Ile Perrot 3d printing montreal 3D Printing Pincourt 3D Printing Quebec 3D Printing Services Canada 3d printing services quebec 3D Printing Student Project 3D Printing West Island Custom Headphones Folie Technique Impression 3D Quebec Polytechnique Montreal Summer Camp Project

McGill Robotics Design Contest: 3D Printed Robot 0

Members of the Mac Robotics Club came to MatterThings with an amazing project: To create a robot using mostly 3D printed parts for the ASABE Robotics Student Design Competition.

The Mac Robotics Club

The Mac Robotics Club consists of students from the Macdonald Campus of McGill University who have a passion for coding, electronics, mechanical sciences, engineering and computer modeling. The club teaches its members to create robotic systems that solve engineering, scientific and mathematical problems using the previously mentioned passions.

Members Ryan Knight, Amanda Boatswain Jacques, Roberto Buelvas and Nicolas Buxbaum make up the team that took part in the American Society of Agricultural and Biological Engineers Student Design Competition, where they entered their 3D printed three-robot system.

Above you can see the members of the Mac Robotics team that took part in the competition.

The ASABE Robotics Student Design Competition

The American Society of Agricultural and Biological Engineers Student Design Competition (abbreviated ASABE), is a competition that is held annually where teams compete to create functional robotic systems which solve real-world agricultural problems.

To quote Amanda Botswain Jaqcues, "this activity gathers teams of university students from the United States, Canada, and most recently China, that will all compete".

This year's competition was focused on "developing a fully autonomous system simulating the pruning process of raspberry primocanes and floricanes". Essentially, that means developing an automated system to prune (to trim away old or overgrown branches) raspberry plants (also known as canes).

The Project

The team's project consisted of a three robot system, all of which used 3D printed parts, which of course, we 3d printed for them.

Pictured above: Mac Robotics Team's three-robot system.

Amanda praised our service, going as far as to say "during the stressful time before the competition, they provided great assistance and even worked after hours to make sure our parts would be completed on time and with no defects".

The team's robot system scored 3rd place among 13 teams!

Have something you want 3D printed? Feel free to contact us using the information below!

MatterThings Inc. - 3D Printing

514-312-6060

www.matterthings.com

3d@matterthings.com

We´re in Pincourt, the West Island of Montreal, Quebec, in Canada

- MatterThings Inc.